Soundproofing

How To Make Walls Quiet

The advent of high quality audio systems and home theaters has changed the building environment completely. Where hotels, motels, homes, condos, and apartments previously only needed to deal with isolating a neighbor’s voice, we must now contend with loud movies coming from next door, even when the sound is simply coming from a good television. Given today’s need for high quality transmission loss in walls, it is important to rethink the original standards of Sound Transmission Class (STC) 34 walls and start thinking about raising the transmission loss by 20dB – 30dB or more, to provide a high quality living environment for all.

Over the years, many techniques have been used to enhance the sound transmission loss through residential and commercial walls. Many of these methods require unusual or difficult construction techniques that may not be followed accurately by an installer. As technology has given way to new materials, the more exotic construction techniques can revert back to standard STC ratings for single wood or steel stud construction. Furthermore, new technology allows easy, fast, and low cost retrofitting in existing structures (including homes and offices) where the existing installed drywall does not have to be removed to achieve large increases in Sound Transmission Class (STC) ratings.

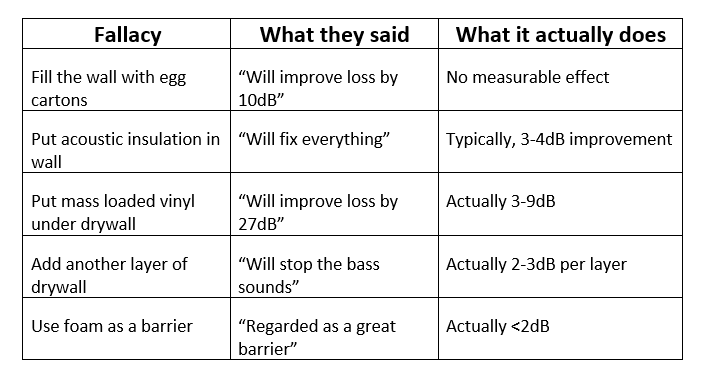

Attempts to quiet rooms over the years have also created many fallacies. Even today, some merchants sell a variety of materials to unsuspecting contractors and homeowners based on fallacies which have been pervasive for years. A few of these are:

As you can easily see, if we are trying to make a 30dB improvement, it will not be achieved with egg cartons and vinyl. These are facts backed by actual lab testing on finished assemblies. Newer noise reducing building materials may reduce cost, labor, risk, liability and mistakes while improving STC ratings and reliability beyond older methods. Most importantly, this guide draws from actual lab and field testing on complete assemblies–it is important to prove how well a specific wall assembly performs. Serious Materials is committed to industry standard STC testing on complete assemblies and references independent lab tests throughout this guide.

What are STCs and Why are They Important?

To understand wall sound isolation, we need to understand the concept of “Sound Transmission Class” (STC). This is a method of gauging sound transmission loss through a wall, as defined by the American Society for Testing and Materials (ASTM). Specifically, STC testing is governed by ASTM E90 and E413 and has been updated and changed several times throughout the past 40 years. The most recent version of testing was approved in 2005. Earlier versions, especially those prior to 1985, measured the transmission loss differently and the STC values presented in those tests may not be equivalent to today’s results. Thus using an STC test from 1974 may not be valuable and the results should be regarded as inferior to more recent testing results. The ASTM standard is accepted by architects, designers, manufacturers, contractors, and distributors of acoustic building products.

The higher the STC rating, the greater the sound attenuation of the acoustic barrier. STC is essentially the average dB loss through a barrier across a range of frequencies (from approximately 125Hz to 4kHz) and fit to a curve. A decibel, abbreviated as dB, is a measure of “how loud” a sound is. An STC rating is the average difference produced by a wall assembly, essentially measured in dB, between the sound in one area and the sound in an adjacent area over several frequency ranges (technically 1/3rd octave bands). Note that STC points do not add up linearly. Adding a barrier, such as Mass Loaded Vinyl, that has an STC of 26 to a wall that has an STC of 34 does not result in an STC of 60. (For simplification, we are using STC points and dB interchangeably, which is not exact, but a close approximation for this overview).This is due to “mass law”, which states that doubling the mass of the entire assembly will only add 5-6dB of transmission loss. Doubling the mass is difficult and requires much more than a single additional layer of vinyl.

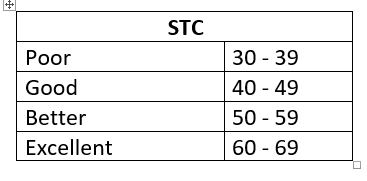

What is an acceptable STC rating for a wall? This depends on what noises may be coming from adjacent rooms. The National Research Council of Canada completed an extensive survey of condo residents to determine noise-unhappiness with actual STC ratings of their walls. The results show that complaints were reduced with walls at 50 or better, and were almost non-existent with STCs of 60 or above.

Table of commonly accepted noise perception in walls:

For multi-family construction, the minimum IBC code is STC=50. However STC=60+ is recommended for party walls in higher quality construction such as hotels, townhomes, condos, and certainly quality home theaters. The FHA recommendations for Luxury Grade 1 dwellings are also 55 to 60.

Perception

People perceive a doubling of sound as 10dB. As such, it takes a 10dB reduction to reduce the perceived “noise” by 50%, 20dB by 75%. etc. By increasing a standard wall’s STC from 34 to 64, there is ~30dB of transmission loss, which would provide an 88% reduction in perceived sound coming through the wall. This guide also demonstrates why adding items that only add 3dB to the transmission loss through a wall have little effect on perceived improvement in noise reduction (3dB is perceived as a 19% reduction in noise and considered barely noticeable by most people).

STC Example: Home Theater

A medium home theater produces sounds as loud as 100dB (and often 110dB). A typical “quiet room” is approximately 30dB to 40dB maximum background noise. To have a reasonably quiet room at 40dB adjacent to a loud home theater with a sound level of 100dB, a wall would have to be rated with an STC of 60 (100–40=60).

Typical existing wall construction (the most common method is wood stud construction with insulation and 5/8” drywall on both sides) has an STC rating of 30 to 34. A room built with standard construction walls adjacent to the home theater would have sound levels at 70dB (100dB minus 30dB), which is far too loud for conversation. However, with a wall built to an STC of 60, the adjacent room would have sound levels of 40dB, almost as quiet as a library.

Note: STC is an average number across a number of octave bands (frequencies) fitted to an agreed-upon curve. Most sound barriers, including those using viscoelastic materials, have a higher loss (performance) at high frequencies than at very low ones. If you want to isolate speech or TV’s, your actual perceived loss may be better than the nominal STC value at those frequencies. However, if you want to isolate a subwoofer, your loss may be less than the nominal STC value– you would need a higher STC value to achieve better sound isolation.

Interior Walls Using Traditional Technologies

Walls with higher STC values have been achieved for years using a variety of construction techniques.

A commonly used technique since the 1960s, on both wood and metal studs, is called resilient channel (RC). These are metal channels that are placed at right angles to the studs. The drywall is then screwed into the channel, being very careful that no screws touch a stud directly. In this way, the drywall is isolated from the studs, thus carrying less noise and vibration to the outer wall.

The example right shows a resilient channel. When installed correctly, RC can typically improve STC ratings by 8-14 points, depending on construction. An important note here is that resilient channel is easily “short-circuited”, or in other words, the isolated sheet of drywall can lose some of its isolation due to mechanical connections between the drywall and the frame or adjacent wall/floor/ceiling. For this reason, very careful construction techniques must be followed. For instance, no screws can ever touch a stud; drywall must not touch floors or adjacent walls or ceilings; no pictures or shelves can be hung on the wall where the fastener screws into the studs, etc. If there is one failure, it can ruin any gain that would have been had. Very careful construction and review by the architect or acoustic engineer is required.

Moreover, since the screws are placed into the drywall, it is impossible to “see” if one has accidentally touched a stud or any other object other than the channel. You may never know with certainty if the requirements have been met without acoustic measurements later. This has been one of the biggest drawbacks of this technique–it is not a sure thing. Recent investigation (often due to litigation) has shown that resilient channel construction has a post-construction failure rate (STC designed value) of 90%. The vast majority of walls constructed using RC in the field are not able to achieve the original lab results or the expected isolation. Given litigation history and concerns regarding party walls, especially in multi-family construction, you must be very careful using this technique.

Other stud arrangements, such as staggered-stud and double-stud increase STC points as well (covered below), but consume valuable space and can nearly double the labor costs in both wood and steel stud construction. Both are effective in adding STC points to a new construction project though neither is practical in a retrofit situation as they require tearing-out the walls completely. For retrofit in existing construction, there have been few choices that do not require demolition. It should be noted that adding resilient channels to an existing wall (over the existing gypsum) will not increase STC values. There is not enough space between the old and new gypsum for RC to work effectively.

A variety of fiberboard-based products have been used to achieve better STC values. The most popular of these is Homasote®* SoundBarrier®*. This board can be used behind drywall to improve STC ratings by approximately 3–5 points over regular gypsum drywall in single stud construction. It is easy to use and inexpensive, but will not result in STCs in the “Better” or “Excellent” range by itself. Using traditional methods, one may have to combine several techniques to increase the STC by 20 points or more.

Another technique that is similar to resilient channel is the use of “sound clips”. These work as well as RC, and in some cases produce better STC results than RC. These clips use a hat channel (a metal channel) attached to the clips which are attached to the studs. While this consumes more floor space than RC and requires more labor, the results can be better. The cost of the clips, channel, and labor can add $3-$4/sq ft to a standard wall, according to a leading manufacturer of clips. This method also relies on panel isolation (similar to RC) and requires essentially the same careful construction methods as RC. It can also fail the same way RC fails (that is the wall must be completely floating and not touch adjacent surfaces).

Acoustical engineering consultants are frequently called to provide expert testimony in issues that result in mediation, arbitration, and litigation. The failure rates and causes of failure have been accumulated over a growing body of such field investigations using STC measurement instrumentation. Often, the acoustical engineer has to invade the wall to determine the cause. Litigation on noise issues is becoming more frequent, and the cost of litigation and settlements are rising rapidly.

While using resilient channels is clearly appealing from a material cost perspective (ignoring litigation risk), homeowners and others may choose this and use it successfully by being very careful of the failure mechanisms. Below is a list compiled by acoustic engineers that people should be aware of before beginning a project:

Summary

Resilient channels pose a significant risk of failure in floor/ceiling and party wall assemblies. Lab specifications showing STC 43-55 often result in field-tested STCs in the 34-38 range. Failures trigger litigation, warranty claims and damage the project brand, reputation, word of mouth, and resale values.

The original RC-1 used in most lab tests no longer exists. USG stopped making the product in 1985. Most test results are based on STC tests conducted 10 or more years ago on different fabrications. As there is no standard for RC channel fabrication, the various resilient channels available vary greatly in their resilient (stiffness) characteristics. Using RC channels that are often too stiff, or that have holes the wrong size or shape, results in reduced STC values. There are few current RC channels available that have recent test results based on their actual fabrication and design.

Dead on arrival. RC channels are thin and prone to damage from shipping or on-the-job storage. Any bend in the channel can cause shorting. We have multiple reports of damaged RC channels that are deployed because by the time the damage is perceived, it is too late to re-order.

The RC channels are placed too close together. If this happens, the composite stiffness of the wall will be too high and will result in reduced sound insulation.

The RC channel is often drawn on the architectural plan and/or installed upside down. In such instances, the weight of the drywall pushes the channel into the studs (instead of pulling it way from the studs when installed properly) thus causing a short circuit in the wall, resulting in poor sound insulation.

The RC channel extends too far and touches an adjoining wall. This error causes a short circuit in the wall, resulting in radically degraded sound insulation.

A screw is placed incorrectly. If a screw accidentally attaches into a stud or touches a stud at any point while the drywall is being attached to the resilient channel, it will short-circuit the wall and result in poor sound insulation. Insufficient gap between the wall with the resilient channel and any adjacent wall. If the drywall attached to the RC channel touches the drywall on the adjoining wall, the wall will be short-circuited, resulting in reduced STC value.

Drywall is not installed properly. If the subcontractor adds drywall that is beyond spec (e.g. adding a layer of Type X to meet fire code), the resulting structure can sag, and the weight of the drywall on the resilient channel can cause the wall to touch the floor, causing a short circuit in the wall, resulting in poor sound insulation.

Electrical junction boxes attached to the stud and to the wall. This common error causes a short circuit in the wall and results in poor sound insulation. This mistake is easy to make with the faceplate, which must also be isolated, or by not cutting enough of the drywall away around the junction box. The same principle applies to ceiling attachments, such as lighting and fans.

Gaps around the junctions. If junction boxes at the wall are sealed with standard caulk that hardens over time (instead of non-drying, non-skinning acoustical sealant), or not sealed at all, this will cause a short circuit (or air gap) in the wall, resulting in poor sound insulation.

Resilient ceiling. If the ceiling is also resilient, the walls and the ceiling cannot touch each other. To achieve this, it is recommended the walls be put up before the ceiling. This is counter to standard drywall installation practice. Actions of other subcontractors. When RC channels are used in floor/ceiling assemblies involving stuffing materials into the open truss, the risk is magnified. Plumbing, HVAC and electrical materials are routinely attached inside the small cavities in ways that guarantee short-circuiting the RC channel.

Green wood warping. Most multi-family housing (such as west of the Mississippi River) is constructed with less expensive green wood, which dries after installation. The drying process can distort the framing by as much as 1/2″ in extreme situations; 1/4″ is common. This torque can bring the RC channel in contact with other elements and cause a short circuit.

Moisture and humidity warping. In high-humidity areas (such as the Eastern seaboard), humidity can bow and buckle drywall, 1/4″ to 1/2″ in many cases. This distortion can bring the RC channel in contact with other elements and cause a short circuit.

Foundation settling. Foundation settling, the third most common cause of litigation, is a regular occurrence. A 1/4″ or 1/2″ settling distortion can bring the RC channel in contact with other elements and cause a short circuit. Language barriers. The high incidence of RC failure contrasts with good results established in the top labs. This discrepancy stresses the need to have highly trained, disciplined personnel supervising and performing the installation. In many construction crews, a large percentage of workers are foreign-born. The ability to communicate in English fluently, understand and execute written and verbal instructions for something as delicate as RC channels is required.

Owner/tenant actions. If, during the life of the property, the owner or tenant installs materials to the wall, such as a picture or lighting, the wall can easily be short circuited. In the case of hotels, many products are routinely attached to the walls, including anti-theft and seismic restraint, bed head-board, writing desks, open shelving system, closet shelving, refrigerator, safe, sconces, mirrors, paintings, bathroom shelving, television wall stands, decorative wall hanging, crown molding, baseboard, wainscoting, etc. For rigidity and security, these products are attached to the studs by screws, which invariably cause a short circuit and significantly reduce the STC rating of the wall. Similarly, if RC channels are used in ceiling construction, any lighting (including track lights and ceiling fans) introduced postconstruction could reduce the ceiling’s STC value. Also, any retrofit for new communication technology that requires a junction box to be attached to the wall will significantly reduce the wall’s STC value. This is particularly risky because the location of the studs and RC channels is hidden and difficult to find post-construction. The wall or ceiling has to be left alone for the life of the property or significant post-construction risk occurs.

Furniture. If the owner (or hotel guest) moves heavy furniture (e.g. bed, desk) against the wall with force, it can cause the resilient channel to bend slightly and touch the studs, thus causing a short circuit in the wall, reducing the wall’s STC value.

Other factors that increase risk:

Availability. The current shortage of steel (i.e. China) has forced RC channels into allocation. Inspections. In several states, RC channels have developed such a contentious reputation that a special inspection must be completed before the wall or ceiling can be closed. Scheduling a special inspection can take several days.

Fiberboard products, which work by adding mass and often isolating the outer layer of gypsum, can be short-circuited in a similar fashion, so care must be taken when using these products.

Mass loaded vinyl (MLV) barrier (typically in sheets or rolls of 1 lb/sq ft) has been available for several years and has gained popularity with hobbyists and those building home recording studios. As stated earlier in this guide, MLV typically demonstrates an STC of 27 alone. It is also true that a single sheet of gypsum board shows an STC of 24-28 depending on thickness. In comparison to another layer of gypsum, the stand-alone STC value of each raw material is similar.

Very few people have been willing to test and publish the STC results, including TL curves, for complete assemblies using MLV. In early 2005, lab tests were conducted at Western Electro Acoustic Labs to test a single stud assembly with MLV laid-in behind the 5/8” gypsum. The test resulted in a wall with an STC of 43, about a 9 point improvement above the wall without MLV. Again, individual STC values of wall components cannot be added, and assemblies must be measured as completed assemblies.

STC Comparisons for Wall Construction

In the past, older technologies utilizing fiberboard (such as Homasote®* SoundBarrier®* 440) or vinyl barriers have been used to gain improvement in STC values. It is important to emphasize that STC values of individual materials do not add-up, adding an STC 27 vinyl barrier to a wall that has an STC of 34 does not result in an STC of 61.

Table 1 summarizes the results you can expect from using various techniques based on actual independent lab results.

Interior Walls Using QuietRock

The QuietRock line of engineered products is a sound isolation system designed to replace standard drywall in any wall (or ceiling) construction including wood or steel studs. QuietRock is a multi-layer laminated gypsum wall product from Serious Materials, Inc.

One major advantage of QuietRock is the ability to use standard construction techniques and achieve high STCs, without the limitations of standard materials– eliminating the need for expensive, difficult nonstandard construction techniques. The wall need-not be “floating”. Simply hang it like standard drywall. All too often, an architect or acoustical consultant designs a high STC wall, only to discover that a contractor did not carefully follow the exact (and sometimes difficult) installation instructions, hence not achieving the desired result. QuietRock is the first technology for walls that cannot be “short-circuited”, thus reducing litigation concerns post construction.

You can use QuietRock panels just like any other gypsum or drywall product. The panels can be cut and attached to the wall similar to drywall. The only difference is that a QuietRock panel is an “internally damped” product which uses constrained-layer damping in several layers inside the panels. QuietRock is available in several performance grades and various sizes (see product specs for exact data), yet is available as thin as 5/8”(like regular drywall) and weighs about the same.

Conclusion

Consumers and office workers are happier with quiet environments. Interior walls with STCs in the 30s are no longer acceptable for most situations, especially home theater, home recording, and multi-family. As a minimum, setting an STC target in the 50s or ideally the 60s results in happier homeowners, apartment dwellers, and office workers. With new technologies, such as QuietRock, it is becoming easier than ever to raise STC ratings with less labor, lower cost, minimal effort, low risk, lower liability, and a high confidence of success.